Manufacturing

The difference between safe and struggling.

Critical Airflow

Owning a manufacturing plant in the heart of South Carolina means we know firsthand how crucial air movement is in hot, humid conditions. Since 1989, Patterson has proudly designed and built our signature high-velocity “blue fans,” now trusted in facilities around the world. Strategically placed, these industrial-grade fans provide powerful airflow that keeps employees cool and comfortable, while also helping regulate equipment temperatures for safer, more efficient operations.

In woodworking facilities, dust and fine particulates can accumulate fast. Our HVLS ceiling fans help keep workspaces clear and breathable while offering relief from hot, stuffy conditions. Plastic manufacturers deal with machinery that emits heat and fumes... Patterson's steady airflow helps move heat away from workers and keeps air quality manageable. Steel and metal fabrication shops operate in high-temperature environments where heat stress is real. Powerful air circulation helps reduce hot zones, improves visibility, and creates a more tolerable atmosphere.

Why Air Movement Matters in Manufacturing

In manufacturing environments, proper air movement isn’t a luxury, it’s a necessity. From woodworking to plastics, from steel to textiles, each type of facility faces unique challenges tied to heat, humidity, airborne particulates, and stagnant air. Without proper airflow, these conditions can quickly compromise worker safety, product quality, and overall comfort.

Best-selling fans for manufacturing facilities.

Airflow Solutions

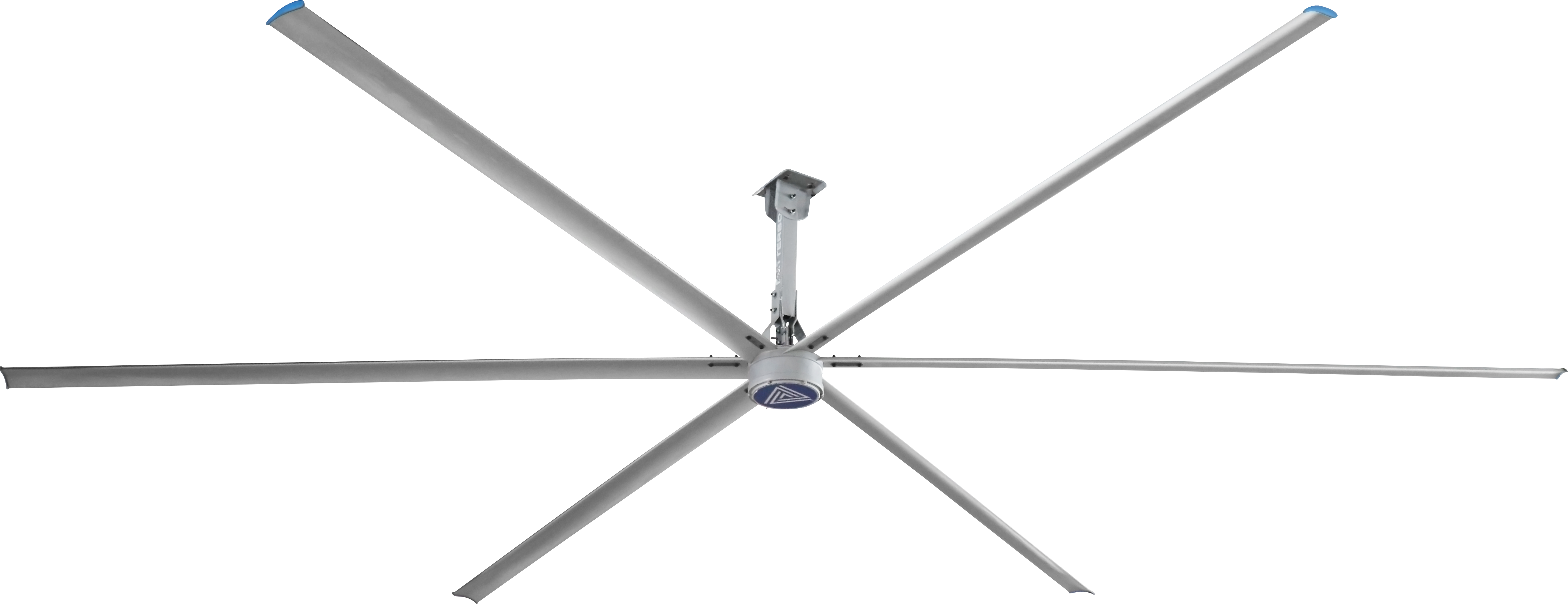

V-Series | Big HVLS Ceiling Fans