Food Processing

Where sanitation matters, air movement delivers.

Condensation Control

Food processing plants are typically harsh environments with condensation from the sanitation process forming on equipment, floors, ceilings, and walls. Contamination from these moist, dripping areas is a critical concern when it comes to meat, poultry, and fish processing plants, and every business strives to avoid an FDA shutdown.

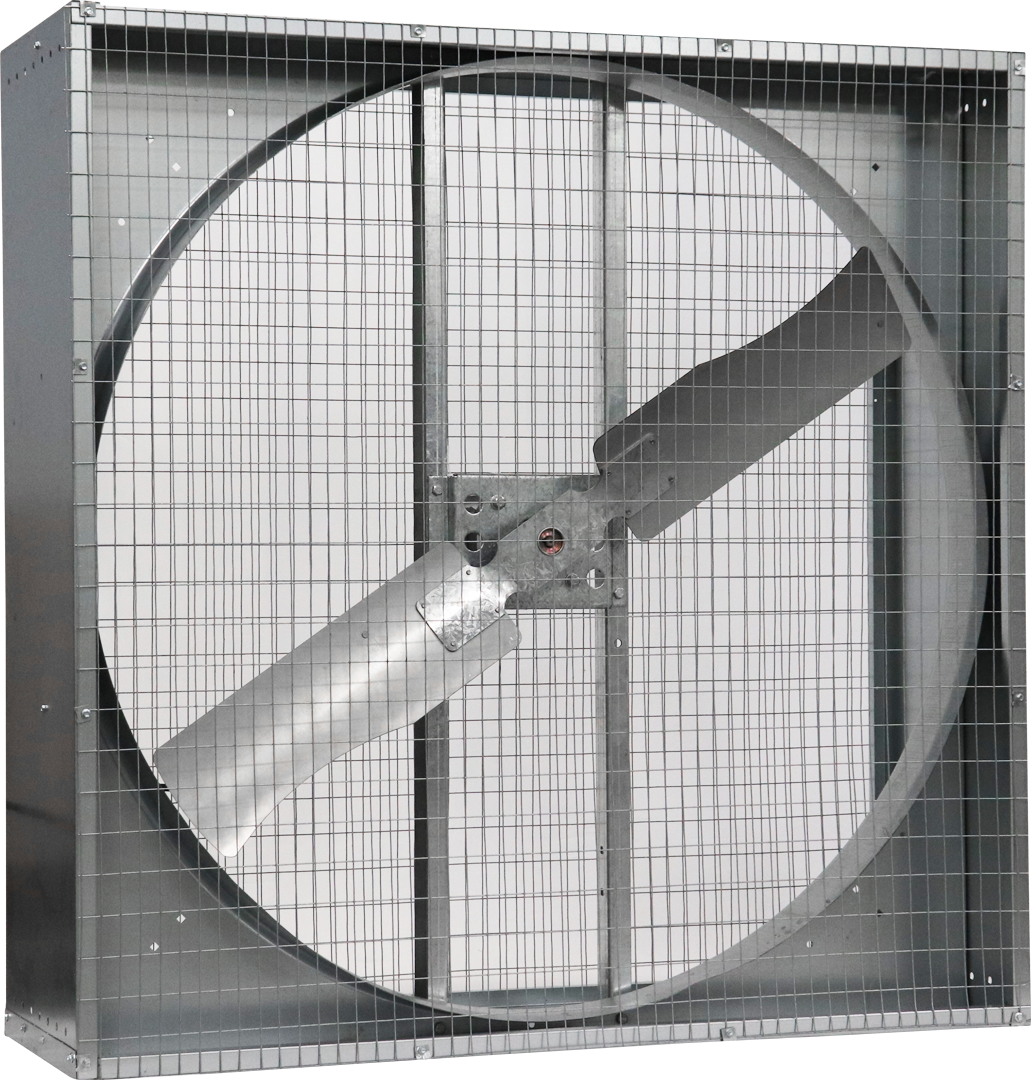

Often called barrel, turbo, hurricane, or air cannon fans, Patterson's high-velocity fans are known throughout the food industry for having the best performance and durability when it comes to air movement solutions. We offer small Workstation Fans to keep employees cool and comfortable during their shift. Interested in something larger? Rather than constantly replacing rusty or corroded fans, our customers are discovering the benefits of high-impact polypropylene and stainless steel spinnings.

Why Air Movement Matters in Food Processing

With the right Patterson fan system circulating air efficiently through your facility, you can reduce condensation - the culprit behind mold, bacterial growth, and slick, unsafe floors. Air movement also helps control temperature and humidity, two major culprits in product spoilage and equipment malfunction. With our expert guidance and support we'll ensure your needs are met!

Patterson fans for meat processing facilities and other wet environments.